Steel Cord Conveyor Belt

Factory: Goldway Conveyor Belt

Views : 664

Category:

Keyword:

Flap

E-MAIL:admin@sdaolonggroup.com

Inquire NowProduct Details

Classification of performance:

Classification of performance:

General Conveyor belt;Cold Resistant Conveyor Belt;Abrasion Resistant Conveyor Belt;Fire Resistant Conveyor Belt

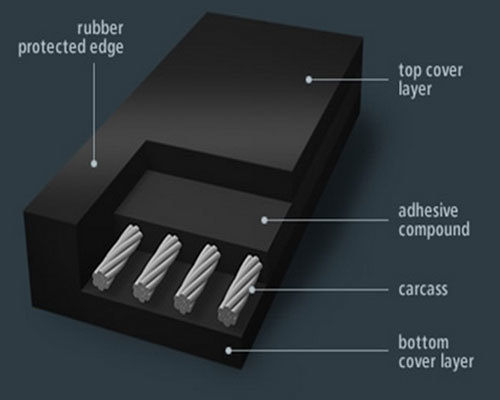

Stucture:

Feature: & Benefits

Feature: & Benefits

1.Zinc Galvanized Open Construction Steel Cord:

Steel cord conveyor belts are designed by selecting cord construction to provide the best specification for a particular application. The cords, made up of many wire filaments, are constructed to provide high flexibility, low elongation and permit efficient and high strength splice designs.

The galvanized zinc coating produces a bonding agent between the cord and insulation gum and provides an important barrier against corrosion.

2.High Tension:

Steel cord conveyor belts satisfy the most demanding and abusive conveyor applications. We have continued to advance the technology for high tension belt to meet need for long overlands, high lifting conveyor systems.

3.Lower Take-Up Travel:

Steel cord conveyor belts are the preferred belt on long overlands and short Stacker systems where minimum belt elongation is a critical design consideration . Steel cord reinforcement elongates a maximum of 0.25% at rated tension , allowing for accepable take -up travel design on long overlands, as well as short Stacker/Reclaimer system.

4.Longer Splice Life :

Dynamic splice test as prescribed in DIN 2231 part 3 proved that the splice life can be as long as the belt life.

5.High Impact Resistant:

Extensive rubber compounding technology has enabled the development of superior insulation gum bonding rubber and cover rubber . Then former penetrates and adheres to the steel cord. The result is excellent adhesion, corrosion resistant and high impact resistant cover.

6.Lower Cost-Per-Ton Of Material Conveyed:

With stronger and longer per roll steel cord belts, the result is less transfer station s, reduced number of splices, lower take-up travel , and lower inventory. These greatly decreases investment cost. Long splice life reduces maintenance downtime and lower cost-tom of material conveyed

Applications:

The belt realized conveying a large amount of materials at long distance and at high speed in the fields of coal, mine, ports, metallurgy, electric power, chemical engineering, etc.

Standards:

Conveyor Belt Can be manufactured following various standards: GB/T7984, GB/T10822, HG3714, HG3782, DIN2210, AS1332, JISK6322.

Belt Construction Nomenclature Example:

ST2000-1600-8+6 Φ5.0 DIN-X

>ST: Code name for steel coed belt

>2000: Tensile strength in warp direction( N/mm)

>1600: Belt width in mm

>6+2:Top and bottom cover gauges( Thickness)

>Φ5.0 : Steel cord diameter(mm)

> DIN-X : Belt standard and cover grade

Technical Parameters:

DIN22131性能参数

Cord Structure

•Production capability:Registered capital of 86 million usd,and total assets of 154 million usd,covering an area of 468,000m2,we have about 1,500 employees,wherein 306 are technical personnel holding medium and senior professional titles.And the annual output of tire,inner tube,flap 6000,000 pieces,conveyor belt is 1500,000 m2,.New equipment is upgrading and increasing every year.

•Sales capability:Over 235 million usd annually

•Testing capability:Our technical labs have always been upgrading for testing the raw materials,production process and finished product.

•Present exporting market:America,Canada,Italy,UK,Brazil,Peru,South Africa,Mid-east,Russia,etc.

Previous

Previous

Related Products